The ROI of Installing a High-Efficiency Heat Pump in Cold Climates

Outline:

– How ROI works for heat pumps in cold climates and which metrics matter most

– Cold-weather performance: what efficiency numbers mean when the mercury drops

– Costs, incentives, and fuel-bill comparisons that shape the business case

– Scenario modeling across different homes and regions to ground expectations

– Tactics to maximize returns, reduce risks, and capture long-term value

How ROI Works for Heat Pumps in Cold Climates

Return on investment for a heating upgrade is more than a quick payback headline. It balances upfront cost, ongoing savings, durability, and risk, all filtered through your climate and energy prices. In cold climates, where winter stretches for months, the math can be compelling because a large share of annual energy use goes to space heating. The first step is to define clear metrics. Simple payback divides net installed cost by annual savings. A more complete view uses net present value, which discounts future savings to today’s dollars, and internal rate of return, which expresses the project as a percentage yield. These tools turn a winter comfort decision into a measurable financial choice.

Consider an example: a whole-home cold-climate heat pump system priced at 16,000 units of local currency, with 2,000 in incentives, yields a net 14,000. If it replaces heating oil and cuts the annual bill by 1,400, simple payback is about 10 years. Now add context. If electricity prices fall due to time-of-use plans you can leverage, or if a weatherization upgrade trims your load, the payback shortens. If electricity rises or the installation undershoots capacity, the payback lengthens. ROI is not static; it is a band defined by assumptions that you can influence.

Key variables include:

– Heating degree days, which estimate seasonal demand

– Delivered fuel costs for oil, propane, or gas, plus fixed charges

– Electricity rates and your access to off-peak pricing

– Building envelope quality and air leakage rates

– Equipment selection and control strategies that manage backup heat

In many northern regions, homeowners see large swings in fuel prices year to year. That volatility is part of the ROI story. A heat pump’s efficiency, expressed as a seasonal average, smooths some of that variance by converting electricity into two to four units of heat under typical conditions. The result is a hedge against fuel spikes. ROI improves further when you factor maintenance. There is no flue to brush, and routine service generally involves coil cleaning, filter changes, and a periodic check of refrigerant charge. Add the quieter operation and zoned comfort many modern systems offer, and the financial return arrives with a tangible day-to-day upgrade—less a gamble, more a measured plan.

Cold-Weather Performance: What Efficiency Metrics Really Mean

Efficiency labels can be confusing until you connect them to what happens on a January night. A high-efficiency cold-climate heat pump relies on variable-speed compressors and smart defrost logic to pull heat from outside air even when it feels impossibly cold. Two numbers matter most. Heating Seasonal Performance Factor (newer HSPF2) summarizes seasonal efficiency across a range of temperatures and cycles; higher values indicate better performance. Coefficient of Performance (COP) shows instantaneous efficiency: a COP of 2.5 means one unit of electricity delivers about two and a half units of heat. In moderate cold around 35 degrees Fahrenheit, cold-climate units often achieve COPs between 2.5 and 3.5. As temperatures drop toward 5 degrees, expect COPs in the 1.8 to 2.5 range for models designed for low ambient operation, recognizing that exact values vary by system and building load.

Capacity retention is the other pillar. Some cold-climate units maintain a high percentage of their rated output well below freezing, which reduces reliance on auxiliary heat. The balance point—the outdoor temperature at which the system’s full output matches the home’s heat loss—shifts depending on envelope quality, duct design, and setpoints. A well-sealed, insulated home might see a balance point below 20 degrees, while a drafty older house may hit that point closer to freezing. When auxiliary heat is needed, choose controls that stage it gently and only as required. The difference between a thoughtfully tuned setup and one that defaults to resistance heat can swing operating costs by hundreds each season.

It helps to visualize the seasonal arc. Shoulder months offer high COPs and long part-load hours, delivering strong savings. Deep-winter stretches involve defrost cycles and capacity management, but modern systems are designed to navigate those hours without a dramatic efficiency collapse. Practical tips bring the metrics to life:

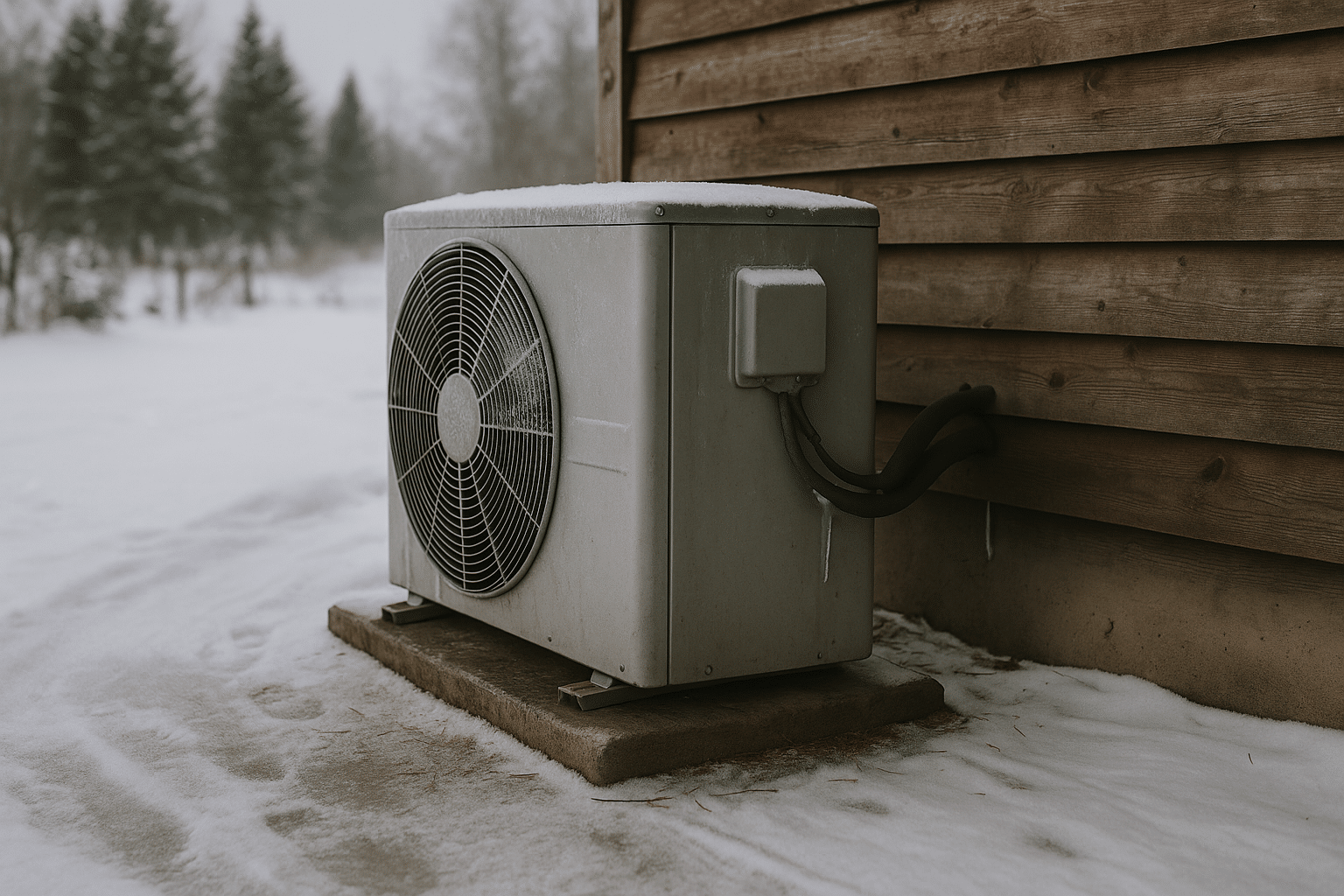

– Keep outdoor units clear of drifting snow and ice

– Mount on a stand to avoid buried coils and improve drainage

– Use a thermostat strategy that avoids large setbacks in arctic snaps

– Seal ducts and improve airflow to lower static pressure and raise efficiency

In short, the label is the starting line, not the finish. The real-world ROI depends on how your system performs across the full temperature curve, and how well your home lets that technology do its work.

Costs, Incentives, and Operating Bills: Building the Business Case

Upfront cost is the hurdle most homeowners see first. For a typical single-family home in a cold region, a high-efficiency heat pump installation might range from roughly 10,000 to 25,000, depending on size, ducted versus ductless design, number of zones, and local labor. Electrical upgrades, such as a service panel increase or new circuits, can add 1,000 to 4,000. Duct sealing or minor distribution fixes may add several hundred to a couple thousand. Many households offset these costs with public incentives—rebates, low-interest financing, and tax credits tied to efficiency and climate goals—plus occasional utility bonuses for demand response enrollment. Always check current local programs; eligibility and amounts change year to year.

Operating costs tell the other half of the story. Rough yardsticks help. Suppose your average electricity price is 0.14 per kilowatt-hour and your heat pump’s seasonal COP is 2.7. That means each unit of delivered heat costs about 0.14 divided by 2.7 per unit of electric input, effectively lowering the cost of heat relative to electric resistance. Compared with oil or propane, many homes in cold climates see substantial savings, especially if fuel prices are high. Against natural gas, outcomes vary. If gas rates are low and fixed charges are modest, savings may be smaller or require time-of-use strategies to improve the math. A household that times some heating to off-peak windows can tilt the economics in its favor.

Consider estimated delivered heat costs using conservative mid-range assumptions:

– Heating oil at 4.00 per gallon with an 85 percent efficient boiler often falls above typical heat pump electricity costs at COP 2.5 to 3.0

– Propane at 2.50 per gallon with an 90 percent furnace tends to be even higher per unit of heat delivered

– Natural gas at 1.20 per therm with a 95 percent furnace can be competitive, but time-of-use electricity or weatherization can restore the heat pump’s advantage

Hidden costs and savings also matter:

– Thermostat and control setup that limits auxiliary heat use

– Snow stands, drip management, and a roof shield if icicles are common

– Annual checkups and filter replacements to maintain efficiency

– Potential reduction of chimney maintenance when fossil systems are retired

– Space gains when oil tanks or old venting are removed

Put together, the business case is a stack of small decisions. Incentives lower the starting line, design choices protect efficiency in the coldest hours, and rate plans shape the monthly bill. When those pieces align, the return is not just plausible; it is persuasive.

Scenario Modeling: Three Homes, Three Climates

Numbers feel real when they live in a house, so let’s visit three. These are illustrative, not promises, but they show how the variables interact.

Case 1: A 2,200-square-foot 1970s colonial in coastal Maine with modest insulation upgrades and new weatherstripping. Annual space-heating load estimated at 55 million BTU based on regional degree days and a blower door result that shows moderate leakage. The homeowner replaces an older oil boiler. Installed cost: 18,000 after a 3,000 incentive. Seasonal COP modeled at 2.6, electricity at 0.16 per kWh, oil at 3.90 per gallon. Annual savings versus oil: roughly 1,600 to 1,900, depending on winter severity. Simple payback: about 9 to 11 years. NPV over 15 years at a 4 percent discount rate: positive in most fuel price futures, with especially strong results if oil spikes happen even twice in that span.

Case 2: A 1,800-square-foot 1990s ranch in Minneapolis–Saint Paul suburbs with good attic insulation and sealed ducts. The home moves from a 90 percent propane furnace to a ducted heat pump with a cold-climate outdoor unit and staged resistance backup. Installed cost: 15,500 after a 2,500 rebate. Seasonal COP at 2.8, electricity at 0.13 per kWh, propane at 2.25 per gallon. Annual savings versus propane: around 1,400 to 1,700. Simple payback: 9 to 11 years. Bonus: time-of-use participation shifts some load to lower-priced hours, trimming 100 to 200 per year beyond the baseline, shaving months off payback. Comfort note: variable speed is appreciated on windy nights, providing steadier indoor temperatures.

Case 3: A 1,400-square-foot townhome in Colorado’s Front Range with a tight envelope and south-facing solar gain. The homeowner replaces electric baseboards with a compact ductless multi-zone system. Installed cost: 12,000 after mixed incentives. Seasonal COP at 3.1, electricity at 0.15 per kWh. Because electric resistance was the starting point, the heat pump reduces heating cost by more than half. Annual savings: 1,200 to 1,600. Simple payback: roughly 7 to 9 years. The homeowner also sees cooling efficiency gains in summer, which are not counted in heating payback but improve overall annual ROI.

These sketches show patterns:

– Replacing oil or propane generally produces strong savings in cold regions

– Replacing electric resistance is a major win due to the COP multiplier

– Competing with efficient, low-cost natural gas requires tighter envelopes, favorable electricity rates, or strategic operation to secure clear returns

The thread running through all three is control of variables. Incentives soften the capital outlay. Envelope improvements protect cold-weather efficiency. Sensible thermostat logic curbs backup heat. With those elements in place, the ROI story moves from “maybe” to “measurable.”

Maximizing Returns: Design, Operation, and Long-Term Value

Great returns do not happen by accident; they are designed. Start with load calculations that reflect your house, not a rule of thumb. Right-sizing matters because oversized equipment short-cycles in shoulder seasons, trimming efficiency and comfort. For ducted systems, test and seal ducts, verify static pressure, and confirm supply balance to far rooms. For ductless systems, place heads where airflow serves actual occupancy, not just where it is convenient to mount. Clear at least a foot of space around outdoor units and elevate them on a sturdy stand. These details add routine costs, but they pay dividends every winter.

Operation is the quiet ROI lever. In cold snaps, avoid aggressive setbacks that trigger long recovery times and auxiliary heat. Choose a thermostat or controls package that stages resistance heat conservatively. If local utilities offer time-of-use rates, pre-warm during lower-priced hours and let variable-speed operation glide through peaks. Keep filters clean, schedule annual tune-ups, and sweep snow away from coils after storms. None of this is complicated; it is more like tending a dependable stove than babysitting a finicky gadget.

Risk management is your safety net:

– Plan for rare polar vortex events with a rational backup strategy

– Add a simple roof shield if falling ice is common above the unit

– Verify condensate management to avoid refreezing around the pad

– Consider surge protection in lightning-prone areas

There are also returns that spreadsheets undercount. A quieter home, more even temperatures, and the flexibility to zone spaces add daily comfort value. Some buyers increasingly look for efficient heating in northern markets; while resale premiums are hard to quantify, energy-efficient upgrades are often well-regarded. On the public side, lower on-site emissions improve neighborhood air, and pairing a heat pump with cleaner grids or local renewables compounds the effect. Over a 15-year horizon, these factors add resilience to your investment. The payback, then, is not just shorter bills; it is a home that performs gracefully through long winters, with savings you can measure and comfort you can feel.